Here you will find information on the treatment (softening/descaling) of drinking water using double softening systems.

Process engineering

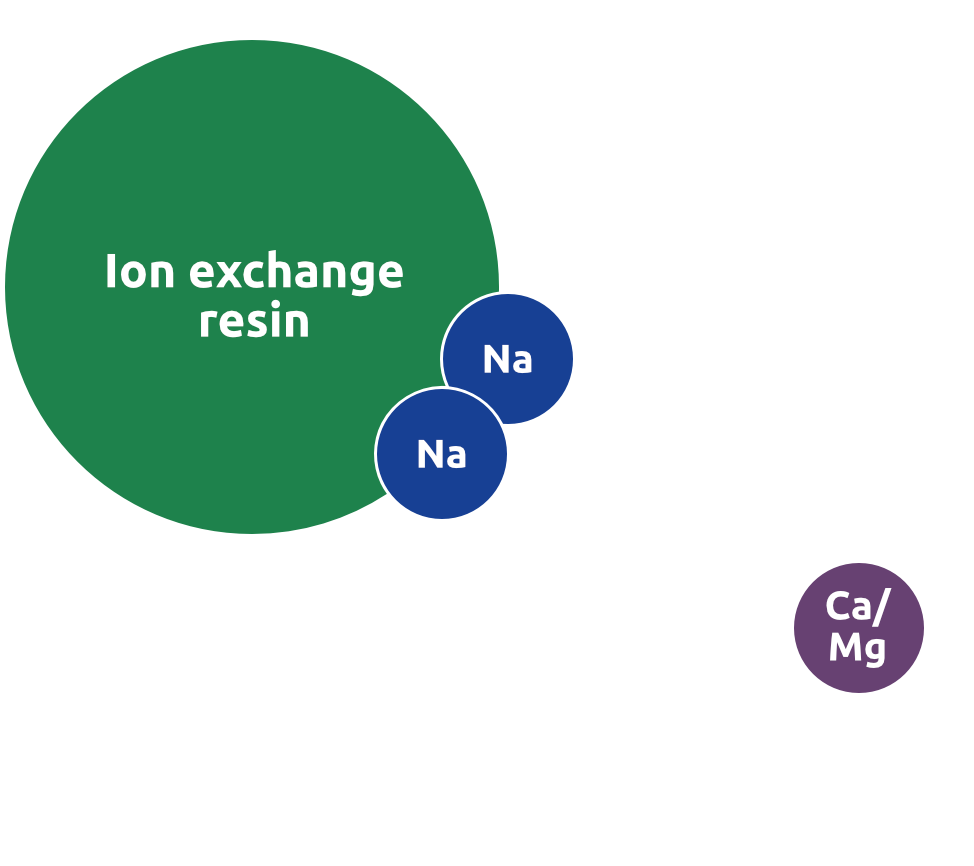

Our double softening systems work according to the ion exchange principle. The water to be softened is passed through an ion exchanger material, which removes the calcium and magnesium hardness components and replaces them with the equivalent amount of sodium ions.

Once the capacity of the ion exchanger is exhausted, it must be regenerated. To do this, highly diluted brine is passed over the exchanger material instead of water. Due to the excess of sodium ions in the brine, the process described above is reversed: the exchanger accumulates sodium ions and releases the retained calcium and magnesium ions. These are flushed out together with the rinsing water as waste water.

All materials that come into contact with the water are food-safe. The effectiveness of the softening process can be verified with easy-to-use test kits. If it is absolutely necessary to prevent the release of hard water when passing over the softening system, the water quality of the soft water can also be monitored fully automatically using appropriate devices (see accessories).

Areas of application

The DWF and DWS series industrial double softeners are used wherever continuously softened water is required and the soft water supply must not be interrupted by regeneration under any circumstances.

Depending on the water quality requirements, the systems are used alone or in combination with other treatment processes:

- Cooling circuits

- Air conditioning systems

- Boiler feed water treatment

- Heating systems

- Car washes

- Rapid steam generators

- Food processing

- Commercial kitchens

- Laundries

- Pre-treatment of feed water for reverse osmosis systems

- Rinsing water for industrial applications

- Industrial plants with a high hardness water supply

Specification

The systems essentially consist of the following assemblies:

- Two filter containers made of glass fibre-reinforced plastic, each with a filling of high-quality food-grade cation exchange material

- One or two control valves made of plastic or gunmetal

- PVC pipework with service valves, shut-off valves and pressure gauges or connecting hoses between the filter tanks

- Salt dissolving tank with sieve bottom and brine valves

- Contact water meter or water meter turbine

- Microprocessor control or electromechanical programme unit for fully automatic operation of the entire system

- and assembly material.

The pipework and controls for the systems are pre-assembled and electrically wired at the factory. For shipping reasons, they are dismantled into individual components before despatch. For systems with a total capacity of up to 300m³x°d per filter container, the containers are already filled with the replacement material at the factory. For larger systems, the filter containers are filled on site as part of the installation work.

For systems with PVC pipework, the complex design of the pipework (4 ball shut-off valves) allows maintenance work to be carried out without interrupting the soft water delivery.

For reasons of operational safety, the operating voltage of the systems is 24V/50Hz as standard. The power supply is either provided by the customer or can be created using a wall transformer (see accessories).

*** Translated with www.DeepL.com/Translator (free version) ***

Assembly

The piping is pre-assembled at the factory, which saves time during on-site installation. A detailed description helps to avoid installation errors.

After filling the filter tanks with the exchange material, the prefabricated piping is installed. Then the on-site water and wastewater connections are connected. Depending on the type of system, a contact water meter is installed in the on-site soft water pipe.

During installation, DIN EN 806, DIN EN 1717, and DIN 1988 as well as locally applicable regulations must be observed.

Functional sequence

After filtration via a fine filter, the installation of which is highly recommended upstream of the system, the water is channelled through the corresponding control valve into one of the filter tanks and softened. The second filter tank is on standby in a regenerated state.

The amount of soft water removed is measured by a meter installed in the soft water pipe and transmitted to the control unit. This registers the available residual capacity of the filter tank in operation.

When the capacity is exhausted, the control system switches fully automatically to the tank in reserve. At the same time, the exchanger filling of the exhausted tank is regenerated.

After the individual regeneration phases of backwashing, salting, rinsing and fast rinsing have been completed, the freshly regenerated tank remains in the standby position until the tank in operation is exhausted and a new switchover takes place.

For systems with microprocessor control, there are additional connection options for dosing pumps, Testomat devices and additional programmes for further solenoid valves, etc.

Raw water quality

Requirements for raw water quality

The water softeners may only be operated with pre-filtered, cold water of drinking water quality in accordance with the German Drinking Water Ordinance TrinkwV2001.

The suitability of other water must be checked by analysing the water. The following minimum limit values must always be observed:

| Temperatur | 1 - 30°C (33,8 - 86°F) |

| Pressure (flow pressure) | 2,5 - 7,0 bar (36 - 102 psi) |

| Max. operating pressure | 7,0 bar (102 psi) |

| pH value during continuous operation | 6 - 8 |

| Free chlorine | < 0,1 mg/l (< 0,1 ppm) |

| Turbidity index max. | 1 NTU |

| Iron content | < 0,1 mg/l (< 0,1 ppm) |

| Manganese content | < 0,05 mg/l (< 0,05 ppm) |

If one or more of the values listed above are exceeded, suitable additional pre-treatment measures must be taken.