High-quality water treatment technology for use in industry and commercial applications.

Specialists for your water treatment systems

Our engineers will advise you comprehensively

Industrial water technology

W.A.L. Wasseraufbereitung Leipprand GmbH stands for clean water and state-of-the-art water technology. We are professionals in the treatment of water.

We have been developing, manufacturing and selling high-quality products and systems for industrial water treatment for more than 36 years. Our experienced engineers use state-of-the-art technology and processes in the construction of our systems and devices for the treatment of drinking and industrial water.

In the more than three decades that W.A.L. GmbH has been involved in the realisation of water treatment plants, our team has realised projects in almost every industrial or commercial application. Our customer base includes manufacturers and suppliers of all conceivable areas of the manufacturing industry, including manufacturers and suppliers of the automotive sector, manufacturers of parts cleaning systems, manufacturers of paint shops, manufacturers of powder coating systems, manufacturers and operators of car wash systems, manufacturers in all areas of the F&B industry, including dairies, cheese dairies, butchers, breweries and many other sectors.

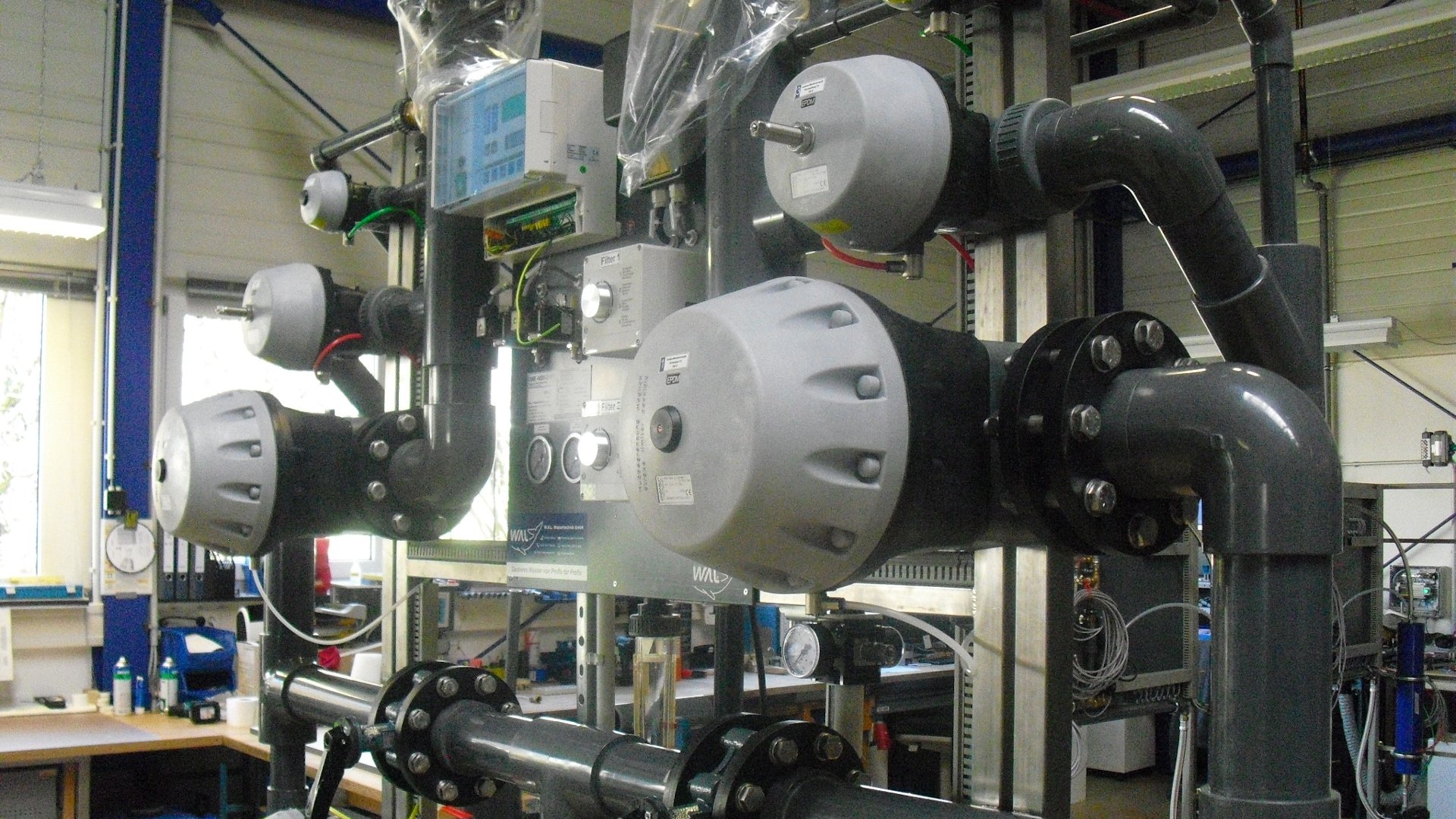

The main fields of activity of W.A.L. Wassertechnik GmbH include the manufacture of systems and devices for water softening as well as systems and devices for the demineralisation of drinking water and well water using the modern and environmentally friendly process of reverse osmosis.

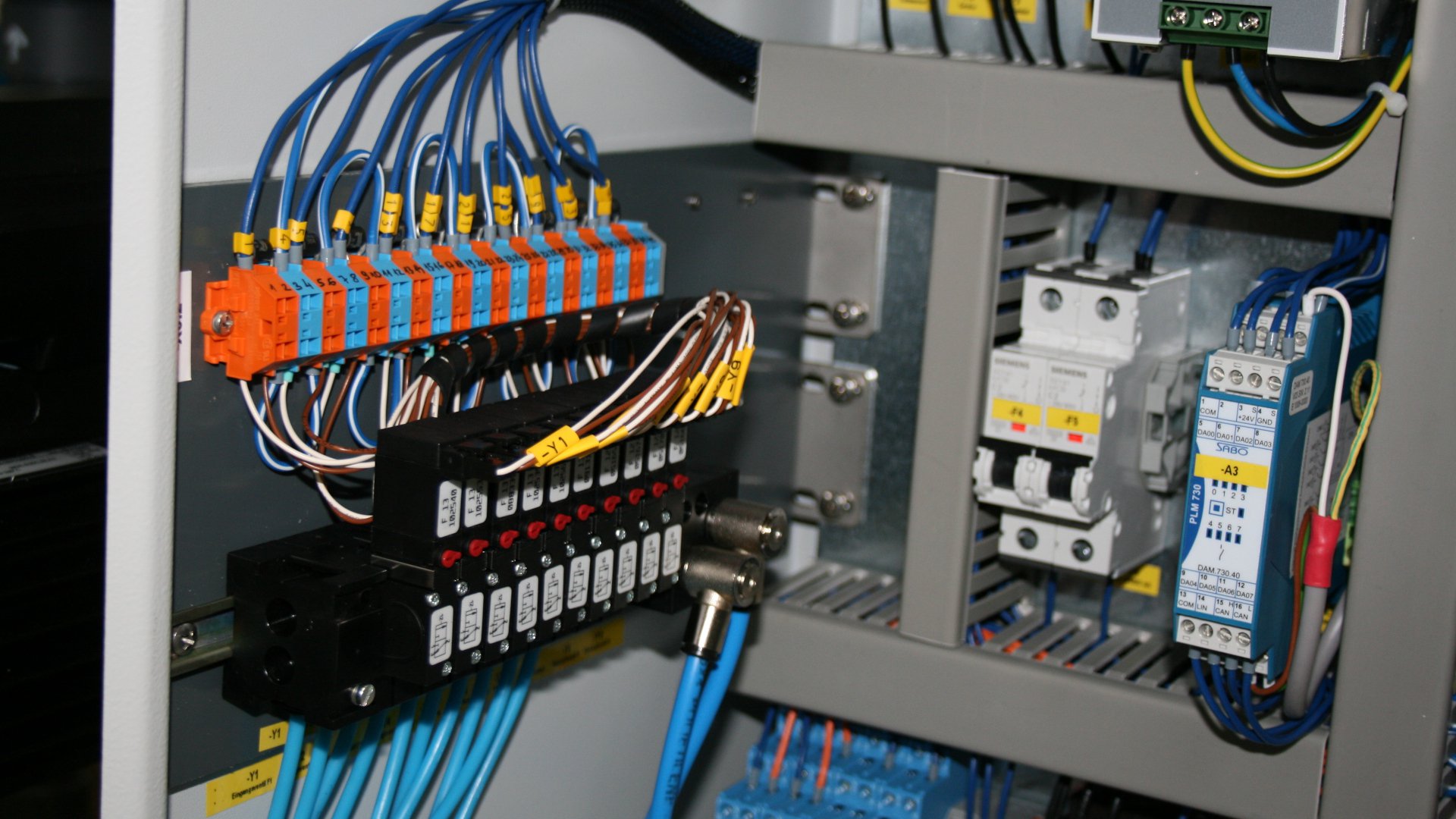

We design and build microprocessor controls, measuring devices and field devices as well as sensors for use in water treatment. We also stock a wide and extensive range of accessories and spare parts such as fittings, tanks, reverse osmosis membranes and reverse osmosis modules. Also pressure vessels and membrane housings. We also supply ion exchanger materials such as cation exchangers, anion exchangers, mixed-bed exchangers and ion exchangers for special applications. We also supply pumps, filter inserts, pressure boosting systems, dosing systems, control technology and much more.

Our service technicians use professional field service management software and a team of operators in the back office supports the field service. This means that we can be on site very quickly and ensure the smooth operation of your water technology. Regardless of whether the system technology operated in your building comes from W.A.L. Wassertechnik GmbH or not.

If there is an emergency with your water technology, do not hesitate to contact us. We are guaranteed to help you! We look after systems from all manufacturers and not just our own W.A.L. systems - that is the core of our service philosophy.

In addition, W.A.L. GmbH is a DEKRA-certified specialised company in accordance with german §62 AwSV (Ordinance on Installations for Handling Substances Hazardous to Water). The certification according to §62 AwSV replaced the well-known certification according to §19 Water Resources Protection Act (§19 WHG) some time ago. This ensures that our service technicians, technicians and engineers are optimally trained in dealing with all environmental hazards associated with water treatment. In addition, regular recurring certification ensures that all current regulations, guidelines and laws are always taken into account by the experts at W.A.L. GmbH in order to avoid environmental hazards.

Professional water treatment technology - a subject of trust

Water is a sensitive topic for good reason, because clean water means life. For 32 years, our customers have placed their trust in the outstanding expertise of W.A.L. Wassertechnik GmbH.

In companies with high water consumption, it makes sense to analyse the water technology and optimise it if necessary. Water is a precious commodity. The availability of water and, above all, drinking water is seemingly inexhaustible in the centre of Europe. Many industrial companies have an enormous water consumption. According to statistics from the Federal Environment Agency, modern and efficient water technology and modern and efficient production processes have continuously reduced water intensity in almost all sectors of the manufacturing industry since the beginning of the twenty-first century. The automated treatment of process water or rinse water is an investment in economic efficiency and sustainability. In most cases, process water treatment systems significantly reduce the amount of water used. They reduce water consumption costs and help to protect the environment.

By using modern methods to treat water for industrial processes, the use of chemicals to condition the water for the respective application can be significantly reduced in many applications. In some applications, the use of water treatment technology even makes it possible to dispense with the use of chemicals for conditioning altogether.

Our highly efficient filter systems and water treatment plants may be the perfect addition to your industrial water technology.

Systems for the production of demineralised water

Demineralised water is fully demineralised water. Demineralised water is deionised and has a very low conductivity. Ultrapure water is required in countless applications to ensure the proper operation of appliances and systems. This demineralised water can be obtained using various processes. These processes are either the classic ion exchange using a combination of cation exchanger and anion exchanger. The modern process of reverse osmosis in combination with downstream mixed bed ion exchangers or combined with electrodeionisation systems (EDI) can also be used to obtain ultrapure water.

If the requirements for ultrapure water are not quite so high, two-stage reverse osmosis systems from W.A.L. Wassertechnik GmbH can also be used. In two-stage reverse osmosis systems, the pure water from the first stage, known as permeate, is further desalinated via a second reverse osmosis stage, thereby further reducing the electrical conductivity of the end product.

Systems with ion exchangers

Ion exchangers remove the ions from the water that are not part of pure water. In the combination of cation exchanger and anion exchanger used in most cases, positively and negatively charged ions are replaced by the equivalent of hydrogen ions (H+) and hydroxide ions (OH-). This is how deionised water is created. The regeneration of such ion exchanger-based demineralisation systems is carried out by rinsing the ion exchangers with acid and alkali. In the vast majority of cases, hydrochloric acid and caustic soda are used for this purpose. For the operation of such systems, this means that only specially trained personnel are allowed to handle the systems and operating materials for health and safety reasons alone. Furthermore, additional complex and expensive operating equipment is required to properly neutralise the waste water produced during regeneration so that it can be disposed of in an environmentally friendly manner.

Furthermore, the chemicals required for regeneration are hazardous to water. As a result, depending on their size, such water treatment plants are systems that require monitoring and must be regularly inspected by an expert organisation.

Reverse osmosis systems

In contrast to systems with ion exchangers, our reverse osmosis systems have many advantages. The reverse osmosis process is based on modern membrane technology. The process does not require the addition of chemicals, provided the reverse osmosis system is operated with softened water. The driving force in reverse osmosis is pressure, which is generated by a vane pump or a centrifugal pump in the system itself. The waste water continuously produced by the reverse osmosis system during operation is referred to in technical jargon as concentrate and contains only the ingredients also contained in the raw water, but in a higher concentration.

Contact us

Please fill out the form to contact us. Summary of your message: