Here you will find information on the treatment (demineralisation) of drinking water using reverse osmosis.

Process engineering

In terms of environmental friendliness, waste water pollution, cost-effectiveness and user-friendly, fully automatic operation, the reverse osmosis process has become established for the demineralisation of water.

As the reverse osmosis process is purely physical, the use of regeneration chemicals is not necessary. Compared to conventional demineralisation using cation and anion exchange, the high costs for handling and storing acids and alkalis are eliminated, as are the costs for neutralising the regeneration waste water.

It must be noted, however, that in many cases pre-treatment of the water to be demineralised is unavoidable with reverse osmosis.

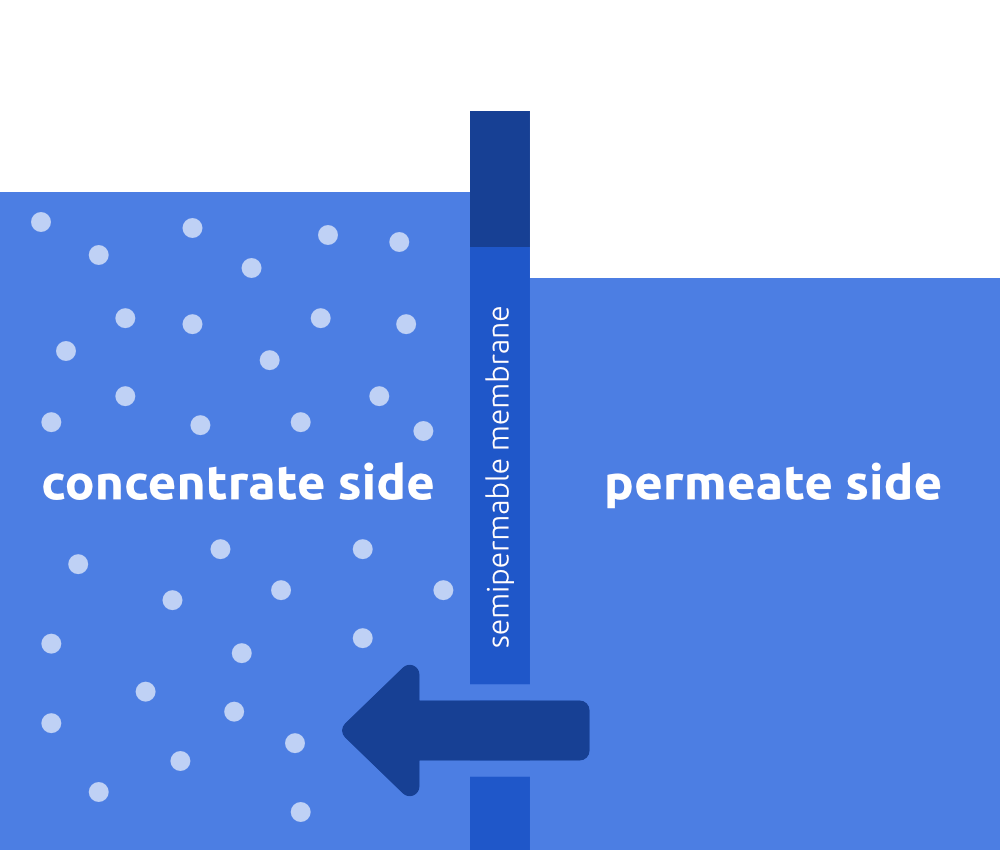

The phenomenon of osmosis occurs when pure water diffuses from a weak salt solution through a semi-permeable membrane into a more concentrated salt solution.

This process is illustrated in the first picture on the right. A semi-permeable membrane, in this case only permeable to water, separates a vessel into two halves. One half of the vessel is filled with a concentrated salt solution and the other half with pure water. Due to the difference in concentration, water from the weak solution (in this case the "permeate side") diffuses through the membrane and dilutes the concentrated solution (in this case the "concentrate side"). The decrease in volume of the weak solution is proportional to the increase in volume of the concentrated solution and the concentrations of both sides become closer and closer.

The constantly increasing pressure on the membrane surface caused by the increase in volume on the "concentrate side" has a diffusion-inhibiting effect and continuously slows down the aforementioned process until it comes to a complete standstill.

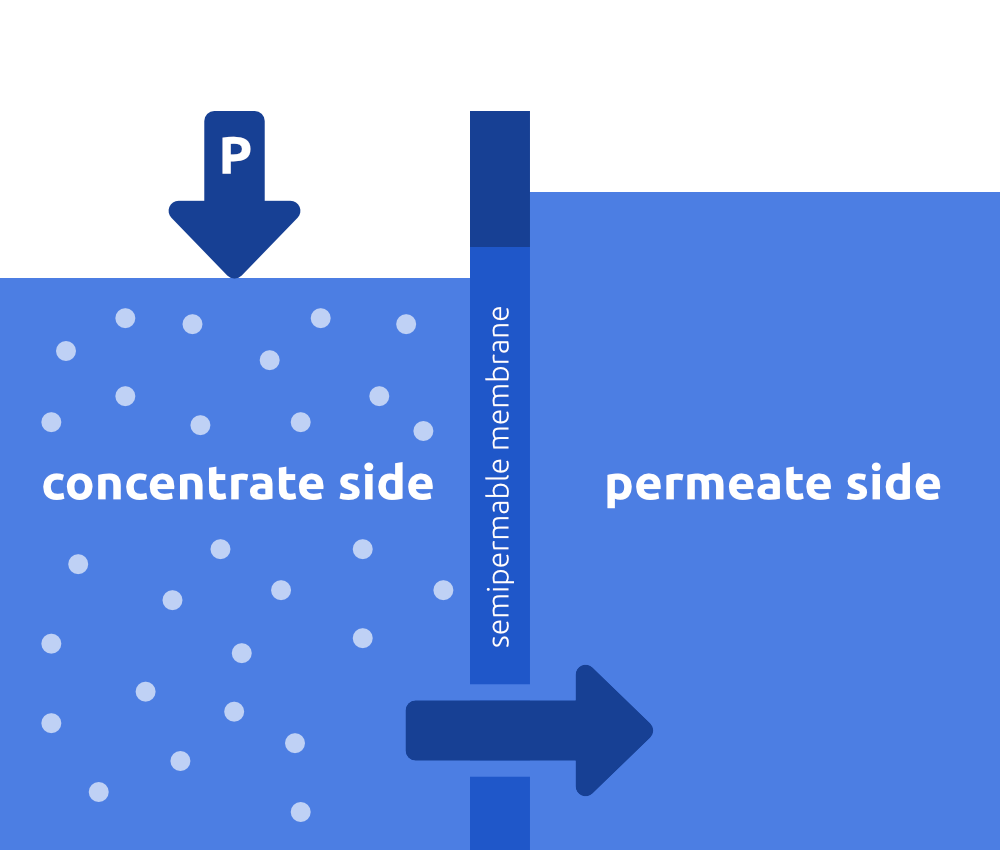

If additional external pressure is now applied to the "concentrate side" of the solution, the osmosis process can be reversed. This process is shown in the second picture.

Areas of application

Our reverse osmosis systems and reverse osmosis devices are preferably used where continuously demineralised water is required. Water qualities with a residual conductivity of less than 1 µS/cm can be achieved through appropriate design or in combination with post-treatment systems.

In accordance with the many usable properties of partially and fully demineralised water, there are many possible applications, only a few of which are listed below:

- Treatment of boiler feed water

- Treatment of drinking water for the beverage industry (brewing water, fruit juice dilution)

- Treatment of drinking water for the food industry

- Treatment of cooling water

- Hotel and catering industry:

- Glass and dishwashers

- Steam cookers (steamers)

- Supply of ice makers

- Supply of coffee and beverage makers

- Nitrate removal from drinking water

- Production of demineralised water for:

- Air conditioning and heating systems

- Batteries

- Cooling emulsions

- Air washer

- Rinsing water in the electroplating industry

- Car washes

- Rinsing water for parts cleaning systems

- Treatment of process water in the chemical and pharmaceutical industry

- Pure water for dialysis stations

Specification

In reverse osmosis systems, the above principle is technically realised. The pre-treated water containing natural salts is first filtered through an ultra-fine filter to remove physical impurities. A booster pump increases the water pressure to the required operating pressure. At this pressure, the water is channelled into the reverse osmosis module(s) in which the membrane is located. The membrane allows pure water to pass through, while the salts are largely retained as described.

During the demineralisation process, a low-salt stream (permeate) and a stream concentrated with the retained salts (concentrate) are produced. A partial flow of the resulting concentrate is fed back to the booster pump to increase the pure water yield. The other partial flow is discarded as waste water if no other utilisation is possible. A microprocessor control system with integrated conductivity measurement monitors the water quality of the permeate fully automatically and regulates the operation of the entire system.

Montage

Our standard series reverse osmosis systems are frame-mounted units, wall-mounted units or units with a closed housing. This design enables time-saving installation of the system on site. A detailed description helps to avoid installation errors.

DIN EN 806, DIN EN 1717 and DIN 1988 as well as local regulations must be observed during installation.

Functional sequence

The desalination process of reverse osmosis systems is based on the membrane diffusion process described above, in which pure water passes through a semi-permeable membrane under high pressure and salts, colloids and other substances are retained by the membrane. The water (feed) supplied to the reverse osmosis system is divided into a pure water volume flow (permeate) and a waste water volume flow (concentrate). The permeate is temporarily stored in unpressurised or pressurised water storage tanks to cover peaks in consumption. The proportion of the concentrate volume flow fed to the wastewater must not fall below a certain minimum, as otherwise deposits (scaling or fouling) may form on the membrane surface, resulting in a drop in system performance. To improve efficiency, the other part of the concentrate volume flow is returned upstream of the pump and passed back over the membrane together with the fresh water volume flow.

Our reverse osmosis systems are equipped with a microprocessor control unit that controls and monitors all processes. Together with the appropriate accessories, the systems can be operated fully automatically.