- 0 - 4,7 m³/h

- Frequency-controlled

Usage

The PE-SC-P series pressure booster stations are suitable for pumping/boosting cold, clear water from unpressurized storage tanks (so-called indirect connection). They are also suitable for boosting pressure in pressurized water networks (so-called direct connection).

The pressure booster stations are used where cost-effective pressure boosting with the most constant delivery pressure possible is required.

- Pumping water from storage tanks

- Pressure increase in tap water networks

- Pumping water from network separation tanks

Functionality

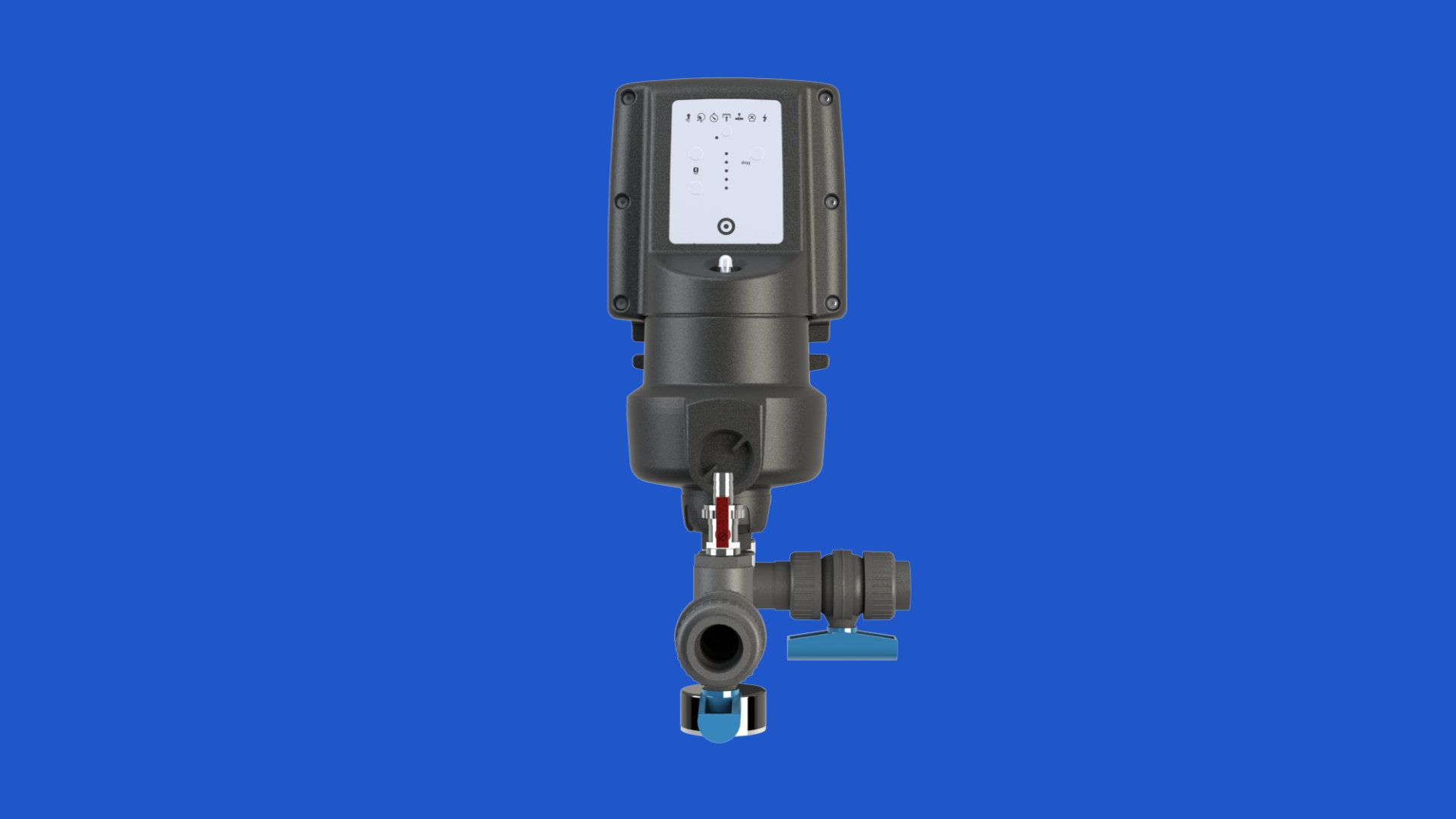

The speed of the electric motor integrated in the pressure booster station is regulated by an integrated frequency converter so that the adjustable delivery pressure is kept constant within the limits of the pump characteristic curve. To implement this so-called constant pressure control, the current actual value of the pump outlet pressure (delivery pressure) is measured with an integrated pressure sensor and compared with the setpoint value set on the pump control. If the setpoint and actual values differ, the control changes the speed of the motor until the actual value corresponds to the setpoint value. The pump control system uses appropriate monitoring routines to determine when no more water is being drawn. If this is the case, the pump is switched off. If the pressure at the pump outlet drops again, the pump switches back on automatically.

Advantages

Compact design

Pressure surge-free water supply to consumers

Self-priming, provided the pump has been completely filled with water

Easy to use

Low electrical power consumption

Integrated leakage monitoring of downstream pipe networks and units

Integrated monitoring of water shortage and dry running

Integrated pressure monitoring

Integrated runtime monitoring

Integrated temperature monitoring

Scope of delivery

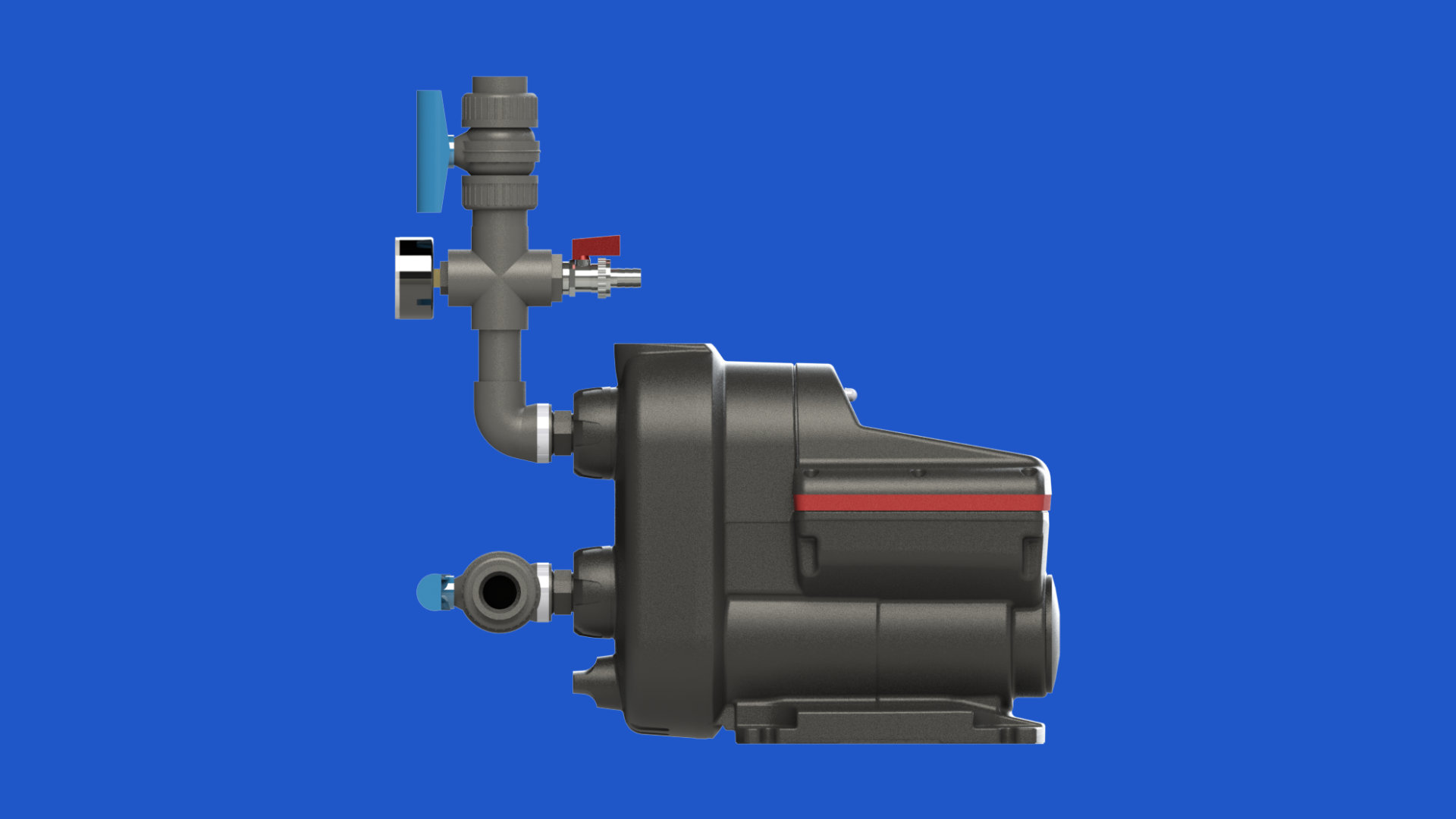

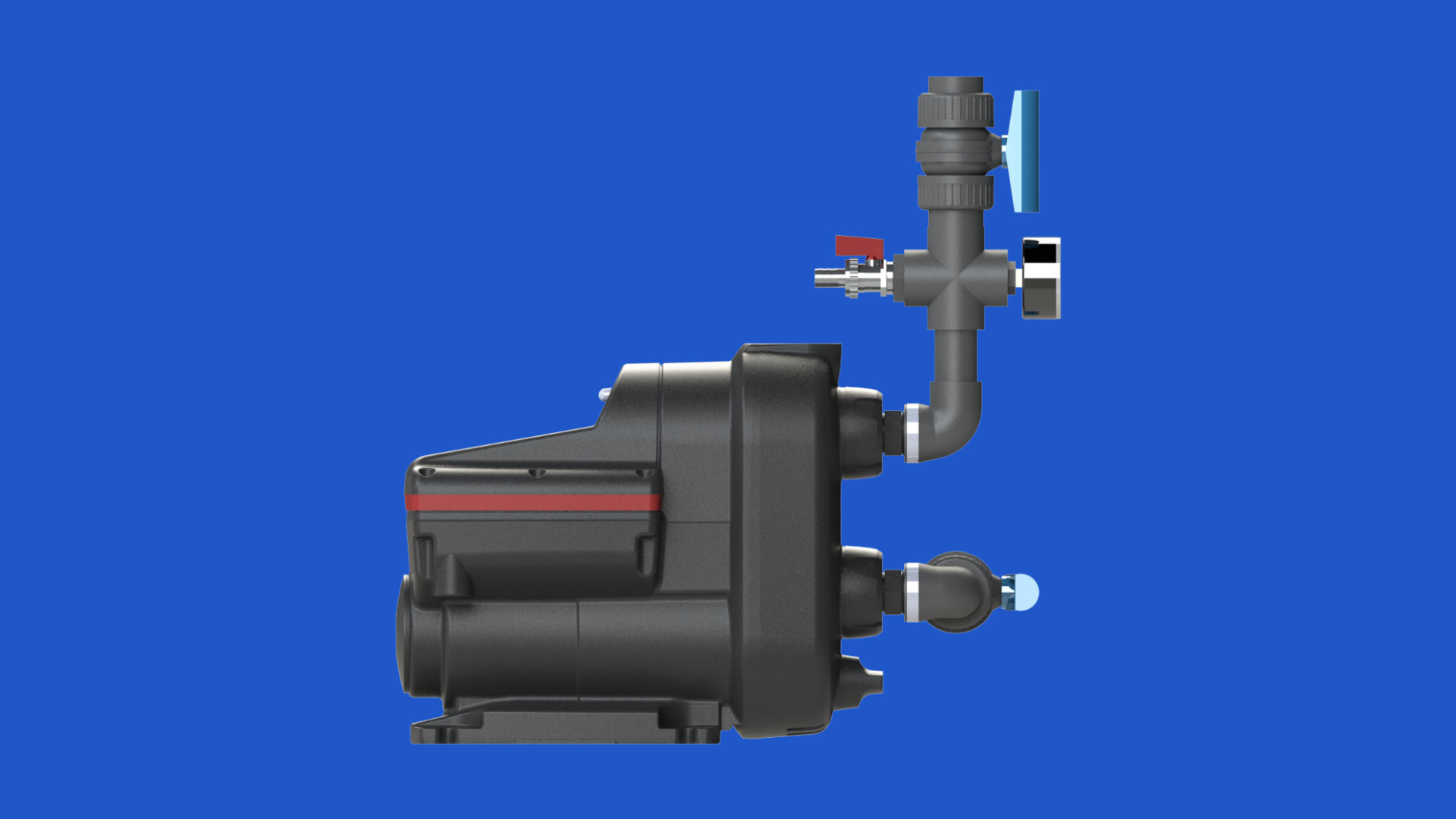

Centrifugal pump with integrated control, diaphragm pressure accumulator, and frequency converter

Suction nozzle with shut-off valve

Pressure connection with pressure gauge, sampling valve, and shut-off valve